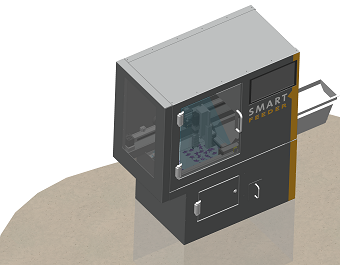

The Smart Feeder fulfills the same function as a traditional vibration bowl feeder; the singling out of bulk and orientation of parts. However, the Smart Feeder has a number of very great advantages with respect to a traditional vibration bowl feeder:

The Smart Feeder is universal, where a vibration bowl feeder is always taylormade for a part.

The Smart Feeder is able to work with more than one part or component. This is a great advantage when more variants of a product are produced or several products are manufactured on one line.

Therefore, the Smart Feeder after the life cycle of a product is re-usable for another product.

Therefore, the Smart Feeder has a quick change over time, a new part or component can be added in a quarter by a teach-in function.

Smart Feeder achieves the same performance as a traditional vibration bowl feeder but for a wider range components in size and mass.

The integrated vision technology makes it possible to do quality checks of parts.

The integrated robotics make it possible to perform simple assembly operations.

Smart Automation has a test setup to demonstrate the usability for your particular parts or components.

Celebration Time! On March 1, 2025, Smart Automation will celebrate its 15th anniversary! A perfect moment to reflect on all the highlights of the past years. We also proudly celebrate the anniversaries of Teun van den Berg (founder and now Commercial Director) and Erna Kolenbrander (Administration). Since the company’s inception in 2010, they have been instrumental in the success of Smart Automation.

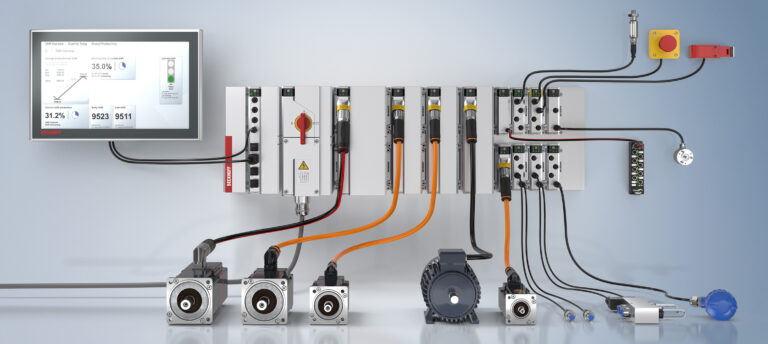

Smart Automation has been a Solutions Provider of BECKHOFF for 12 years

Smart Automation has been the solutions provider for Beckhoff for more than 12 years. During this period, Smart Automation has focused on building specialty machines with Beckhoff equipment as the beating heart of our solutions, always using the latest technologies.

Our engineers at Smart Automation are fully trained and have developed their own tools to make optimal use of Beckhoff equipment. We have designed our own user interface that not only offers an optimal experience for machine operators, but also for technical departments and service providers. This interface adapts to the PLC/Machine control and peripheral equipment such as measuring equipment, printers, central databases, and more.

Although Smart Automation also carries out projects based on other platforms, we can build the most flexible interfaces with Beckhoff. With our expertise and experience, we ensure that your projects run smoothly and meet your specific needs.

Contact us today to discover how Smart Automation can take your projects to the next level with our tailor-made solutions.

Smart Automation uses robotics in more and more automations that we develop and realize for our clients. As a result, we now have extensive experience with different brands and types of robots. Often combined with vision.

We have extensive experience with robots from the brands Omron, Kuka, ABB and our own developed portal robot based on Beckhoff. And for vision we often use Omron, Cognex or Sensopart. We have successfully deployed from accurate 6-axle robots to super-fast Delta pickers.

If you are interested in what robotics can do for your production, please feel free to contact us.

As a builder of machines and production lines that sometimes do their work for decades, Smart Automation has a great responsibility towards the environment. We are well aware of this and make the following considerations:

In this way we try to limit the footprint within our sphere of influence. If you are interested in our approach, or if you still see room for improvement, we would be happy to discuss this with you.

Smart Automation celebrated its 10th anniversary this weekend. We had a wonderful weekend in Bergen aan Zee with our team and partners, with Sky diving, good food, sports activities on the beach and lots of fun.

Smart Automation has completed a compact machine for wirelessly encoding of chips in identification documents.